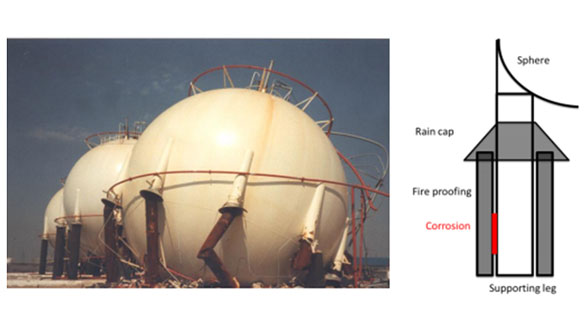

Many foundation structures in refineries such as skirts of process columns and the supports of spherical storage tanks (Horton spheres), are covered with a layer of fireproofing for safety reasons. Small cracks or holes in fireproofing may cause ingress of water, resulting in corrosion underneath the covering. The deterioration process cannot be detected by Visual Inspection alone. Failing to adequate condition monitoring tools, the deterioration process may eventually cause the foundation to collapse with disastrous results.

Corrosion Under Fireproofing (CUF) is nothing different than Corrosion Under Insulation (CUI). So is there any solution to detect Corrosion Under Fireproofing / Insulation without even removing fireproofing or insulation?

Yes, Pulsed Eddy Current (PEC) is the solution you were looking for!

So what is Pulsed Eddy Current (PEC)?

Pulsed Eddy Current (PEC) is an advanced electromagnetic inspection technology used in detecting flaws and corrosion in ferrous materials typically hidden under layers of coating, fireproofing, or insulation.

Why PEC for Corrosion Under Fireproofing?

- No need to remove insulation, cladding, asbestos, fireproofing, concrete, coating over test materials, thus eliminating the operating asset’s downtime

- PECT can be applied at high temperatures up to 550°C of metal under insulation

- Measurement accuracy of ±10% of measured wall thickness

- PEC testing can be performed on insulated layers up to 250mm thick

- Test over corrosion scabs or blisters. No need of surface preparation thus cost saving for the plant owner

- PEC is an Inservice inspection which is not affected by flow of fluids within the subject equipment, thus no shutdown required

- Battery powered instrument, thus perfect for remote locations

- PEC is a fast screening tool

Standards guiding PEC Inspection : ISO 20669